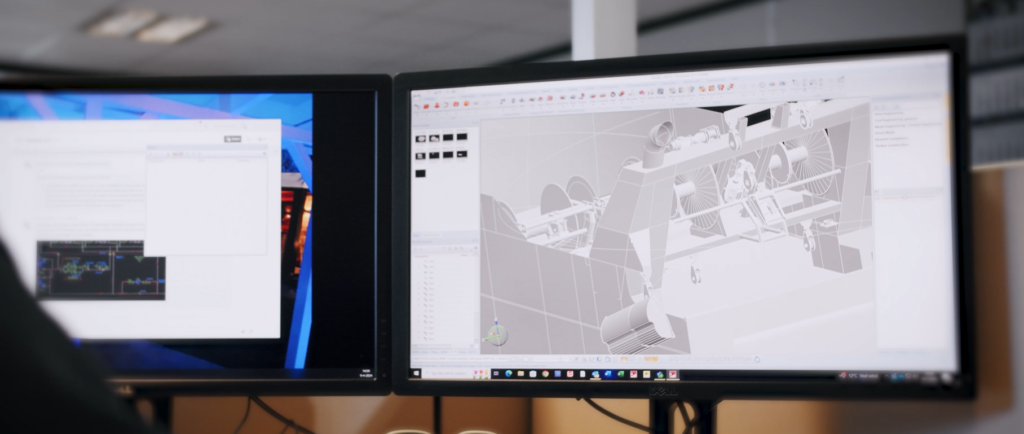

A modern and well-equipped machine fleet

VCU TCD is equipped with a comprehensive and modern machine park, featuring lathes, milling machines, CNC-controlled press brakes and guillotine shears, plate rolling machines, MIG, MAG, and TIG welding systems, and a high-precision waterjet cutter.